ISO Tanks - Hire, Sales and Engineering Solutions in Australia

ISO tanks are designed to store and transport bulk liquid or powders. They are commonly found on road, rail, sea, at manufacturing facilities or on-site at remote mining locations.

ISO tanks, or ‘tanktainers’ as they are commonly known, have been around for a long time, with commercial production beginning in the mid 1960s. As demand increased in the early 1970s, the shape and design evolved, with the tanks becoming one of the most versatile containers globally.

Contents

- What is an ISO Tank?

- What does ISO stand for?

- How do ISO Tanks work?

- Why type of cargo does an ISO tank hold?

- How big are ISO Tanks?

- How much do ISO Tanks hold?

- What are the types of ISO Tanks?

- Designed for Supply Chains

- Designed in Australia for Australian Conditions

- What is the difference between an ISO Tank and a Flexitank

- ISO Tank Container Services

- Bulk Liquid Storage for Larger Volume

What is an ISO Tank?

An ISO Tank is a stainless steel cylinder set inside an engineered steel frame, the dimensions of which are consistent with a standard 20-foot container. The tank itself is made of a layer of steel that holds, protects and in some cases insulates the cargo.

Also referred to as a Tank Container or an ISOTainer, ISO tanks are designed with common dimensions, locking features and connections, which means cranes and other material handling devices can easily connect to the tank and move it from vehicle to vehicle.

The common frame also enables ISO tanks to be stacked, which benefits the ease of handling and storage.

ISO tanks adhere to the specifications set by the International Organisation for Standardisation (ISO), which specifies and promotes high industrial and commercial standards. These standards ensure the tank containers are suitable and safe for transport on road (truck), rail (train) and sea (ship).

For ISO tanks, the standards dictate how they are manufactured and conform to regulations such as quality, size and durability. The tanks are inspected and certified to confirm that these standards are met.

ISO tanks are specifically designed to store or transport bulk liquids, such as industrial chemicals and food grade liquids, or powders, like cement and fly ash.

They can be filled from the bottom or from the top, through one or more large hatches, which can be sealed close once filled.

Most tanks are discharged through a butterfly or ball valve at the end of the container. The operator mounts the trailer, connects a hose and then releases the cargo into its next destination.

ISO Liquid tanks carry many types of chemicals, like acid, ethanol, fertilisers, flammable liquids, oils and water. Gravity drives the discharge system, which is located at the lowest point of the interior.

Some highly concentrated chemicals, like acid, can be too corrosive for the interior of an ISO tank. If you know exactly what you plan to store or transport, an SCF tank specialist will be able to identify the best tank container for your cargo.

Powder

ISO Pneumatic tanks carry powders, like cement, lime, fly ash and more.

Their discharge system differs from liquid tanks. Powder is pressurised and correctly agitated inside the tank, which fluidises the powder. It then takes on the properties of a liquid, to ensure its safe and efficient removal.

These ISO tanks are de-pressurised for transport and storage for safety reasons and engineering requirements. A pressurised vessel requires significantly more engineering that impacts the cost of each unit.

Food

Food grade containers are used to transport or store cargo, like milk, chocolate, beer and more.

In addition to some of the standard features on ISO liquid tanks, food grade tanks have a Cleaning In Place (CIP) feature which enables the operator to thoroughly clean the interior to ensure the next load is not wasted, spoiled or tainted.

Depending on their end use, they also have additional features. For example, a milk tank is heavily insulated to maintain temperature for long distance trips. In contrast, temperature control is critical for chocolate tanks, which are heated so the cargo can be discharged as liquid, instead of it setting solid inside the tank.

How big are ISO tanks?

The footprint of an ISO tank is consistent with a 20ft shipping container. The volume can vary, but the size doesn’t change for the purpose of stacking and transporting on ships, trailers and trains.

ISO Tank Dimensions

| Litres | 14,000 - 26,000 |

|---|---|

| m3 | 14 - 26 |

| Length (mm) | 6,058 |

|---|---|

| Width (mm) | 2,438 |

| Height (mm) | 2,591 |

| Tare (kg) | 2,500 - 3,500 |

|---|---|

| Payload (kg) | 32,500 - 33,500 |

| MGW (kg) | 36,000 |

What are the types of ISO tanks?

There are different types of ISO tanks that are designed for specific types of cargo. Different materials call for different discharge types, whilst food requires additional features to ensure repeat use doesn't damage or spoil cargo that is destined for human consumption.

ISO Liquid

ISO Liquid tanks are designed for hazardous and non-hazardous liquids. Some units come with baffles to reduce liquid movement during transit.

ISO tanks have multiple safety feature designed to prevent pressure build up both during transit and discharge.

Pressure Relief Valve (PRV)

The PRV is designed to prevent an ISO over-pressurising during transit. These valves also come in dual action to prevent over or under-pressurisation during cargo movement.

Air Relief Valve (ARV)

To discharge liquid from a tank safely, SCF ISOs have an ARV at the top of the tank. This can be activated from ground level to open the tank to atmospheric pressure, prior to unloading to ensure the tank does not over-pressurise during discharge.

Discharge is completed from the end of the tank.

ISO Liquid Tank

ISO tanks are characterised by a steel cylinder connected to 2 end frames that are equipment with corner castings. The tank meets the ISO standard dimensions, to ensure it integrates into the global intermodal supply chain.

Breathe Easy Indicator

SCF's Breathe Easy Indicator (Patent Pending) provides the operator with a visual indication about whether the top valve is open or closed. When the indicator is green, the Air Relief Valve is open and contents of the tank can be discharged safely. When it is red, the Air Relief Valve is closed it is not safe to discharge the contents of the tank. This SCF invention removes the potential for the tank to be imploded during discharge.

Air Relief Valve

The Air Relief Valve as seen from the top of the tank. This needs to be open prior to discharge so that the tank will not implode. This is connected to the Breath Easy Indicator (Patent Pending) to notify the operator whether it is safe to discharge or not.

ISO Side Discharge

ISO Side Discharge tanks are designed for liquid.

Similar to ISO Liquid tanks, they have all the necessary safety features to ensure operators are kept safe.

However unlike the Liquid Tank, the discharge system is on the side of the tank. This enables the operator to discharge the tank from the ground, without having to work from height on top of the trailer.

Side Discharge

The Side Discharge tank performs the same role as an ISO Liquid Tank, however discharge is completed from the side, instead of the end. This is a safer way for the user to operate the tank, as they do not have to alight a trailer to perform discharge. It can be done safely from the ground.

Interlinked Discharge

The Discharge Valve is connected to the Air Relief Valve at the top of the tank, so the operator doesn't have to release pressure through a separate process. This is much safer for the operator, who is also able to perform less steps to complete discharge.

Air Relief Valve

The Air Relief Valve as seen from the top of the tank. This needs to be open prior to discharge so that the tank will not implode. This is connected to the Breath Easy Indicator (Patent Pending) to notify the operator whether it is safe to discharge or not.

ISO Pneumatic Tank

ISO Pneumatic tanks are characterised by the claw like rails. They also have a piping configuration on one side for loading and discharge.

ISO Pneumatic Gen 4.5

The Gen 4.5 ISO Pneumatic includes fork pockets for easy movement and trasnfer.

Manlid

The manlid is used for loading. Once opened, powers can be quickly and safely loaded into the tank.

Pressure Gauge

The Pressure Gauge displays the internal pressure of the tank. To discharge, pressure is raised to 1.5 Bar. As the contents unload, the pressure drops slowly to indicate the reducing volume. When the level is at .2 Bar, the tank is considered empty.

Pressure Load Inlet

The Pressure Load Inlet is an alternate loading option. Using pressure, powder can be transferred from a vessel to the tank. This method can reduce the amount of dust through the transfer process.

Safety Valve

The Safety Valve prevents over-pressurisation in the tank. It is a critical safety feature than ensures the tank does not reach a dangerous operating presure.

Discharge Valve

The Discharge Valve is used to release the load. Once the air pressure inside the tank builds to a certain level, the powder will be 'pushed; through this valve once opened by the operator.

Tank Vent Valve

Equalise tank to atmospheric pressure at conclusion of discharge. Prevent build up of pressure during transport. Not transporting pressure vessel - both internal and external pressure.

Pressure Load Vent

Allow venting of tank during pressure loading. Need air to escape as you load. Dust cover to be installed or wrapped during operation. Without the need for opening the manlid.

Air Inlet Valve

In order to discharge the tank, air needs to be pumped into the tank via the Air Inlet Valve to build up pressure.

ISO Food Grade

ISO Food Grade tanks are based on liquid tanks, but come with additional features to ensure the inside of the tank can be cleaned appropriately between use.

The Cleaning in Place (CIP) system, which uses spinners on the inside of the tank to evenly distribute water and cleaning solution, enables operators to clean them effectively at designated cleaning stations. These are often part of a logistics company’s network.

Discharge Valve

Cargo is discharged through this valve. A Testing Pot (top right) and thermometer well (top left) enable the operator to test and monitor the cargo precisely.

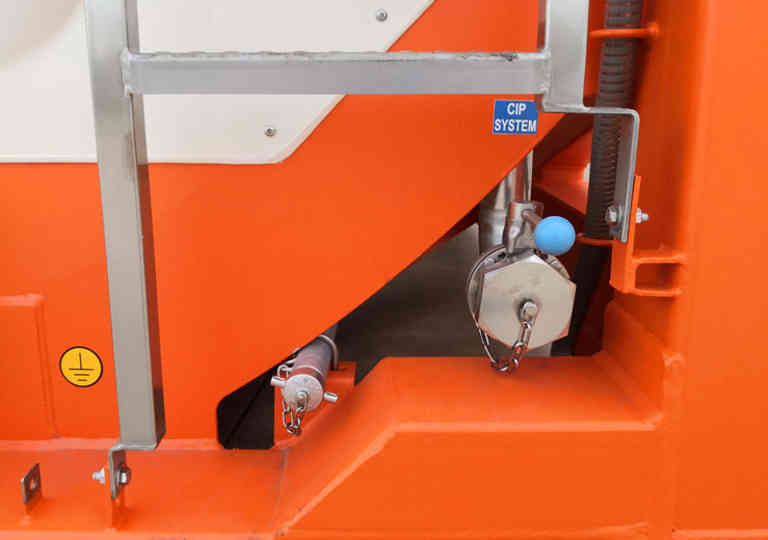

Cleaning In Place (CIP)

Food Grade tanks come with Cleaning In Place, which enables the operator to connect an appropriate fitting to run an internal rinse through the container. Logistics providers often have multiple locations littered throughout a region where the operator can stop and complete a full internal wash.

Thermometer

The in-built Thermometer indicates the temperature of the internal walls. For a more precise reading on the cargo temperature, a well is located near the discharge valve where the operator can attach another thermometer that interacts directly with the cargo.

Discharge, Air Line and Glycol

Cargo is discharged by shifting the main lever into the Open position. The Glycol Outlet enables the operator to distribute a heating or cooling agent between the tank walls to help maintain cargo temperature. The Air Line is used to equalise pressure stop the chance of a tank implosion.

Hygienic Hatch

The Hygienic Hatch protects the Discharge Valve from the elements when not in use. It ensures the cargo is discharged through a clean mechanism.

ISO tanks are designed to fit effectively into existing supply chains. They can be used to transport bulk liquids or powders by road, rail or even sea.

It is common for the cargo to be filled close to the source, transported and discharged on site. The tank cargo can also be dropped at a location where it is drawn from over a period of time, as required, rather than at a set particular time, which places greater pressure on schedules.

Once the cargo has been discharged and the tank is no longer required, it will be cleaned at an appropriate washing facility ready for the next cargo.

Unlike fixed, purpose built trailers, they can be safely and quickly moved from road to rail, and vice versa. This increases the flexibility for the operator, who can transport the cargo long distances with limited resources (e.g., a truck driver). Typically the use of ISO tanks is substantially less costly than operating an ‘over the road’ tanker, particularly if rail haulage is utilised.

Designed in Australia for Australian conditions

SCF ISO tanks are designed for Australian conditions. Working closely with clients, our tanks are designed by our in-house engineering and projects team. Tanks are delivered from factory fully certified and in an unused condition to the major logistics hubs in Australia.

All tanks in our fleet have a detailed service history, and our specialised tanks team is able to prepare your tank/s prior to use. So you can be confident that any SCF tank you hire or buy, whether it is new or second hand, is fit for purpose.

What is the difference between an ISO Tank and a Flexitank?

ISO tanks are purpose built stainless steel containers that can hold liquid or powder. The cargo is loaded directly into the tank and protected by a stainless steel interior and a robust exterior.

A Flexitank is a bladder, originally developed by the US army in the 1960’s, that is put into standard shipping containers and then filled up with liquid. They are popular for the transportation of bulk liquid, like wine.

They provide added flexibility for the end user, who only needs to source an empty shipping container, which up until 2021, has been relatively simple. The Flexitank sits within the container and can hold up to 24,000L.

Compared to IBCs and drum storage, they can hold more cargo capacity.

Whilst they are popular for non-hazardous liquids, Flexitanks cannot be used to transport or safely store hazardous liquids. They are also designed for single use to ensure there is no contamination between usage. Whilst this does increase efficiency, it also places greater pressure on the environmental impacts associated with disposing of Flexitanks. They also cannot be fully discharged, so valuable cargo is lost each trip.

With the global container shortage in 2021, the availability of standard shipping containers in Australia and the associated increased costs to hire or buy has eroded the benefits of Flexitanks.

This is where ISO Tanks come into their own. They can be used to store or transport both hazardous and non-hazardous liquids. An ISO tank can be loaded directly from the source and discharged without the need for additional packaging material.

It is designed for repeated use, following a thorough clean, which is a service offered by many tank suppliers, including SCF. Currently there is also a fleet of available Tanks that can be deployed on short notice.

Certain ISO tanks also come with a range of additional features, like Cleaning In Place (CIP) systems for food grade cargo, superior thermal insulation to maintain temperature sensitive cargo or the ability to mount a motor and heat cargo.

All of these features are not available on Flexitanks.

A tank wash is more than just a spray and polish. It requires a dedicated facility with raised platforms so a skilled team can work at heights without any risk to their safety. This clean includes the exterior, which is self explanatory, but also the interior of the tank, to remove any cargo residue.

In addition to the raised platforms, or gurneys, the tanks are parked in a bay with an isolated drain so all cargo can be collected safely, without entering the wastewater network.

The process can differ slightly as a result of the time between cleans and the internal cargo. The interior of the tank is washed with a specialised hot water rinse with some cleaning chemicals. These are dispersed from a hose with a sprinkler head inside the tank.

Depending on the interior condition and previous cargo, some additional rinsing or active scrubbing is required to remove stains or pitting, or to polish. Tank cleaning professionals with Confined Space Entry Permits or equivalent are required for this type of work.

The washing solution is discharged into a dedicated drain which is isolated from the main waste water network. It is treated and stored in a purpose built tank and regularly tested before it is approved by the relevant authorities and agencies, then released back into waste water.

Tanks are designed to last over many years. They spend most of their life in Australia’s harsh conditions, being lifted, loaded and stacked. As a result, the outer frame and shell can be scratched, dented or grazed at times.

This damage doesn’t always impact the tanks performance, but sometimes repairs are required to prolong its life. This can result in dent removal, reinforcements and welding repairs.

Gaskets and seals are at the greatest risk of deterioration due to their repeated use. Issues like fluid loss or pressure problems can be an indication that some maintenance or repairs are required.

These components can be repaired, or in the worst case, replaced for a relatively low cost. This can put a new lease of life into a tank and prolong its life. SCF’s tank teams in Melbourne and Queensland have dedicated ISO tank professionals who are able to complete repairs that meet ISO tank standards.

In other states, SCF engages third party tank specialists for ISO tank repairs. No matter where your fleet is located in Australia, SCF can provide the support you need to ensure your cargo keeps moving.

Periodic testing is undertaken at set intervals to comply with the necessary regulations. Certification is required to transport hazardous materials, and will be issued at the successful completion of this testing. SCF is able to prepare ISO tanks and then conduct testing, which is witnessed by independent surveyors who are able to certify the tank.

On a liquid tank, a hydrostatic test is conducted. Hydrostatic testing sees the tank tested to working pressure, plus an additional 10%. This is a good opportunity to identify leaks, as fluid can be seen escaping the unit if there are damaged seals. It is referred to as a 6 bar hydro test.

In Pneumatic tanks, an air test is completed for certification, also referred to as a 1 bar air test. Soapy water is applied to the joints and fittings so leaks can be identified as a measured amount of pressure is applied to the inside of the tank.

Surveys

Tank surveys are completed at two stages. An Off Hire survey is done at the conclusion of a lease, when the unit is de-hired into a depot.

An In Service survey is completed prior to going out on hire to certify a tank before it enters service. This is dependent on the criteria set by the client or end user of the tank. It effectively ensures the tank is safe for its intended use.

Modification

Sometimes a project has a unique requirement that cannot be met by a standard tank. Basic modifications can be completed to make them fit for purpose, however due to the nature of tanks this can be cost prohibitive.

Instead it is better to have a clear understanding of the end use and then work with a tank supplier who can design a tank with all the features you need. Getting a tank built at a factory for purchase or long-term hire makes more commercial sense and will perform as required for your project.

Bulk Liquid Storage for larger volume

ISO tanks can be used for bulk liquid and chemical storage. For larger requirements, there are other alternatives - Bulk Liquid Storage tanks.

Ranging from 25,000L to 77,000L, they can be connected into a tank farm configuration to hold in excess of 1 million Litres. It is common to find cargo types such as drilling fluid, oil based muds, water based muds, water and oils in these tanks.

Bulk liquid storage tanks are popular for construction dewatering at the early stage of a project. In metropolitan areas, they can be double stacked, which helps with the critical challenge of limited space available on a construction site.

If you are involved in a construction project and need bulk liquid storage tanks for dewatering, contact SCF. We are also able to supply a broad range of site sheds, storage and dangerous goods containers, so you can deal with one supplier for all your site storage needs.

Take a Closer Look

45ft Bulk Liquid Storage Tank

48ft Wheeled Bulk Storage Tank

Call us today and speak with someone about your ISO and Bulk Liquid Tank needs.